BuildYourCNC

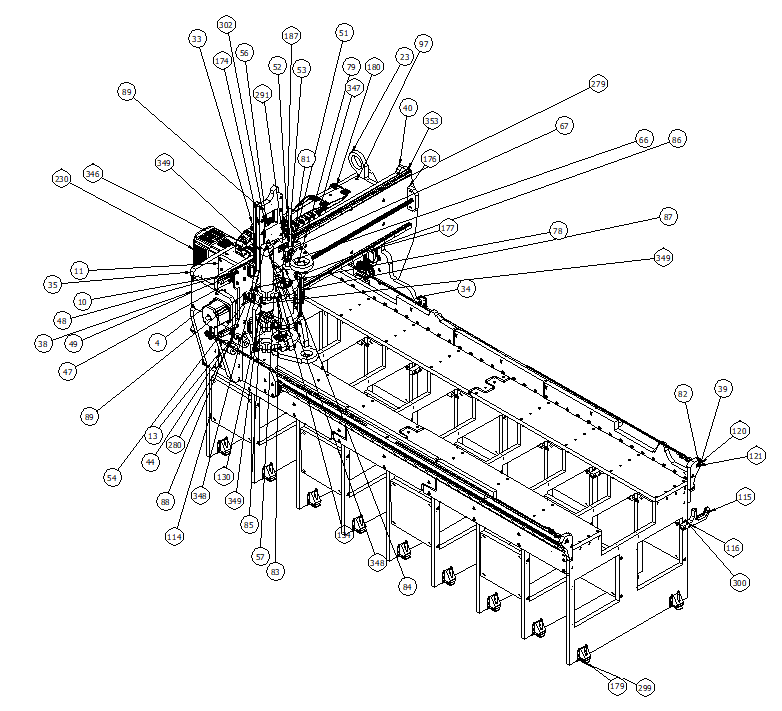

greenBull v2 Small (2'x4') CNC Router Digital Plans

greenBull v2 Small (2'x4') CNC Router Digital Plans

Couldn't load pickup availability

Transform Your Woodworking with Digital CNC Router Plans for the Compact greenBull v2

Step into the world of advanced woodworking and crafting with our DIY CNC Router Digital Plans for the compact greenBull v2. Perfect for home workshops and small businesses, these 40-50 page digital plans are your blueprint for building a versatile 2'x4' CNC router that combines power with practicality. From crafting custom signs to precision parts and furniture components, this router makes CNC technology accessible while maximizing your available space.

Premium DIY CNC Router Digital Plans

Format: Digital Download (40-50 Pages)

Delivery: You will be able to download immediately after purchasing.

Key Features

Comprehensive Bill of Materials (BOM)

- Detailed, easy-to-follow list of all components and materials needed to bring your CNC machine to life

- Organized for efficient procurement to save time and eliminate guesswork

- Optimized parts list for the compact footprint, reducing overall build costs

Space-Efficient Design

- Perfect 2'x4' working area ideal for most common project sizes

- Compact footprint allows for easy placement in home workshops and garages

- Portable design enables relocation when needed

- Reduced material costs compared to larger machines

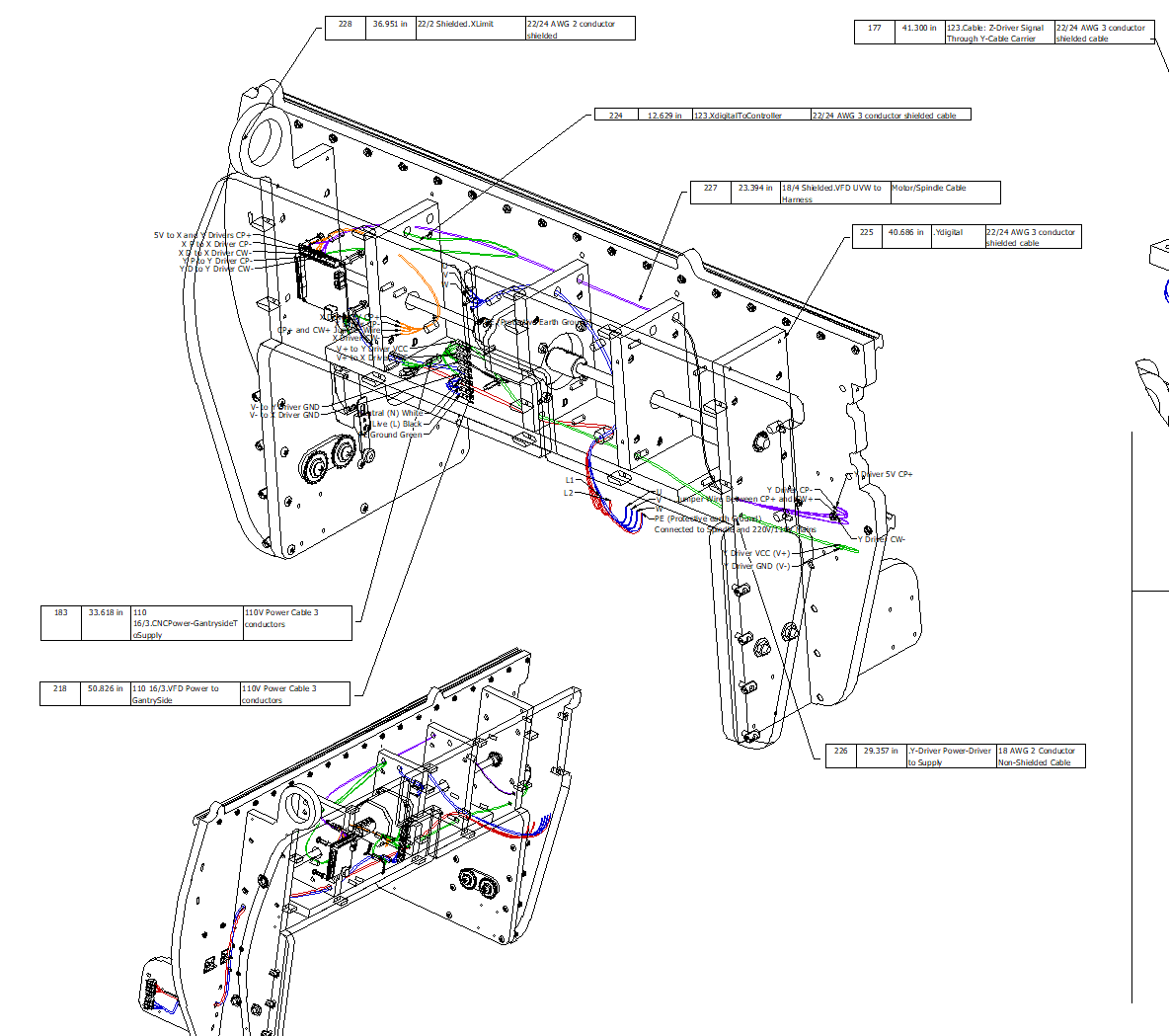

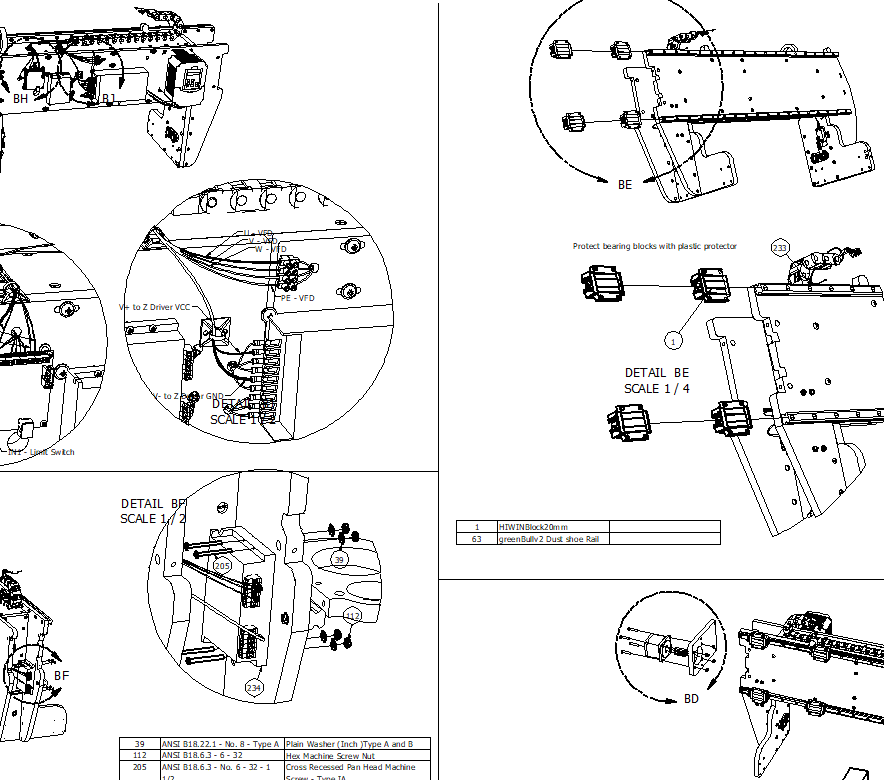

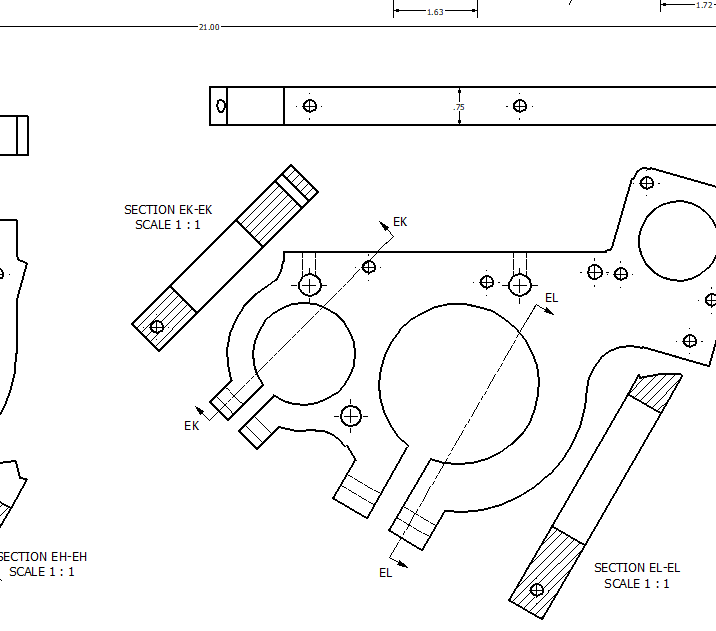

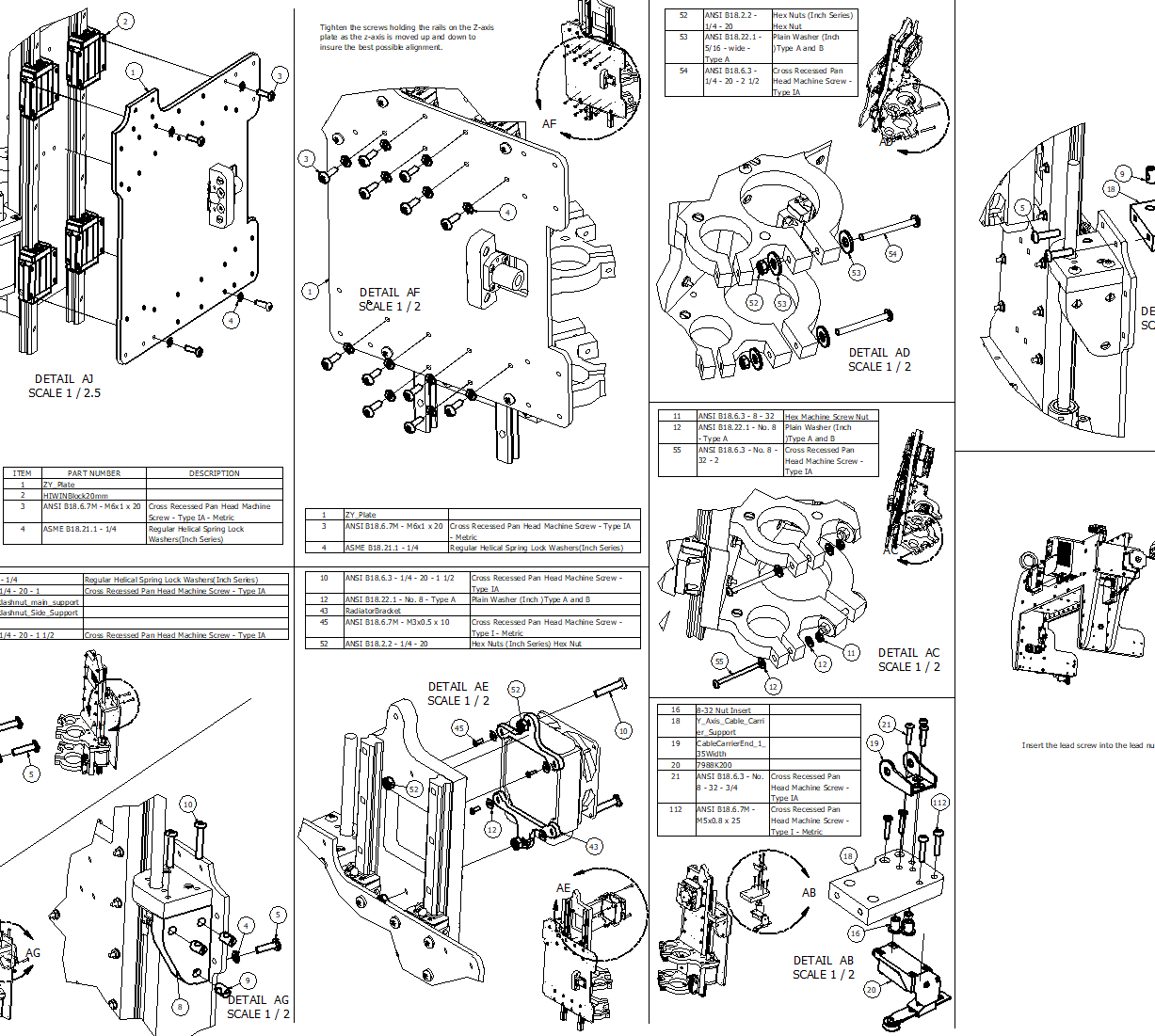

Step-by-Step Assembly and Wiring Instructions

- Detailed guidance ensures a smooth building experience

- Includes clear illustrations to simplify complex steps

- Simplified wiring layout optimized for the compact design

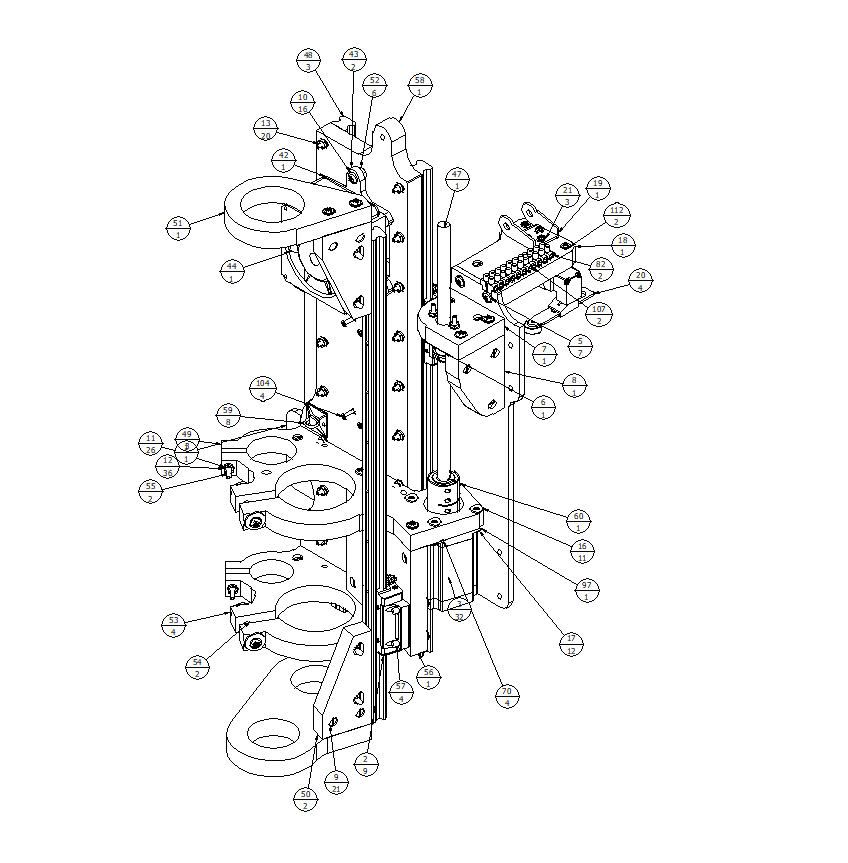

Optimized Z-Axis Design

- Achieves an impressive 7-inch Z-axis travel, enabling detailed CNC milling and cutting

- Perfect for intricate projects requiring depth and precision

- More stable Z-axis performance due to shorter gantry span

Advanced CNC Spindle Integration

- Plans guide the installation of a 220V 2.2kW water-cooled spindle

- Compact design reduces vibration and increases accuracy

- Ideal power-to-size ratio for typical workshop projects

High-Performance Mechanical Movement

- Roller chain system on the X-axis and high-accuracy lead screws on Y and Z axes

- Shorter axis travels result in increased rigidity and precision

- Reduced maintenance requirements due to optimized component sizing

Durable Materials and Premium Construction

- Built with Medium Density Overlay (MDO) for moisture resistance

- Enhanced with Aluminum Y carriages and steel rails meeting HIWIN standards

- Simplified frame design reduces assembly time while maintaining strength

Advanced Electronics Setup

- Comprehensive wiring plans for integrating Mach3 USB controllers

- Detailed instructions for NEMA 34 stepper motors

- Compact electronics enclosure design for clean installation

Optional Enhanced Features

Integrated Laser Gantry

- Add a laser gantry for dual-functionality

- Perfect size for most laser engraving projects

- Ideal for prototyping and small production runs

Innovative Sunken Area for 4th Axis

- Compact table design with efficient sunken area for 4th axis integration

- Perfect for small rotary projects and detailed work

- Maximizes workspace utility in limited areas

Digital Plan Format and Usage

- File Type: Delivered in DFWx format

- Printing Requirements: Can be printed on standard or large format paper

Why Choose This Compact Design?

Perfect for Home Workshops

- Fits easily in single-car garages or small workshop spaces

- Reduces noise and dust impact due to smaller working area

- More manageable power requirements for residential settings

Ideal Project Size

- Perfectly sized for most common woodworking projects

- Handles sign making, cabinet parts, and furniture components

- Excellent for prototyping and small production runs

Cost-Effective Solution

- Lower material costs compared to larger machines

- Reduced power consumption

- More affordable spindle and stepper motor options available

- Smaller dust collection requirements

Enhanced Precision

- Shorter axis travels result in better accuracy

- Reduced vibration due to compact frame design

- More rigid construction possible with smaller spans

Digital Download Policy

Due to the nature of digital content, all sales are final. Once purchased and delivered, digital plans cannot be returned or refunded. Please review all details carefully before making your purchase.

Discover the Compact greenBull v2 in Action

Explore the potential of the compact greenBull v2 through curated videos showcasing its capabilities:

- Perfect precision for smaller projects

- Ideal for home workshop integration

- Space-efficient operation and storage

Transform your workshop with the compact greenBull v2 CNC Router Digital Plans. Build your own precision CNC machine that perfectly balances capability with workshop space!

A Tutorial on the Simple use of the greenBull v2 CNC Router

One Way to Recover a CNC Job in the Middle of a Cutting Process

The CAD, CAM and CNC Milling Process (One Method)

- Stepper Motors 425 oz-in (3 are needed)

- 4.2 Amp Drivers (3 are needed, one for each stepper motor)

- 48V Power Supply (For the motors/drivers, only one is needed)

- 24V Power Supply (For the controller)

- Mach3 USB Controller (Least Expensive and easiest to integrate)

- Pokeys57CNC Controller (More difficult to integrate, but very feature rich)

- ESS (Ethernet Smooth Stepper Controller) Optional: C25XP to make wiring easier for the ESS

- Rotary Axis Limit Switch (Adjustable)

- Snap Action Limit Switch

- #25 Idler Sprockets 20 teeth 3/8" ID (5 are needed)

- #25 Drive Sprockets 1/4" ID 9 teeth (3 is needed)

- #25 Roller Chain (Quantity will depend on the final travel dimension of the X and Y axes)

- Coupling 1/4" to 1/2" (one is needed for the Z-Axis)

- Rails (two for each axis. Lengths will differ depending on the built travel dimensions). This item is not stocked since I am not able to compete with price, but Amazon or AliExpress have them for a lesser price. Make sure to get the same specifications found in the link.

- Rail Bearing Blocks (12 total, 4 per axis). This item is not stocked since I am not able to compete with price, but Amazon or AliExpress have them for a lesser price. Make sure to get the same specifications found in the link.

- For this machine, I recommend using MDO (Medium Density Overlay). This is a plywood product (not fiber board) and has a bonded overly on both sides to protect against moisture. Most lumber yards carry this product as it is used in the concrete forming industry and for outdoor signage. These boards are more expensive than other plywood like birch or maple.

- Hardware is best purchased through bulk retailers since there are high quantities needed for this CNC build. Check the plans for the necessary quantities and types.

Share

Questions & Answers

Have a Question?

-

I was wondering if components such as the boards would have to be made by myself or if some of them can be purchased?

If you are referring to already cut wooden parts of the structure of the machine, I cannot provide this. This machine was also available as a kit in the past with all of the cut boards, but I don't offer this anymore.