BuildYourCNC

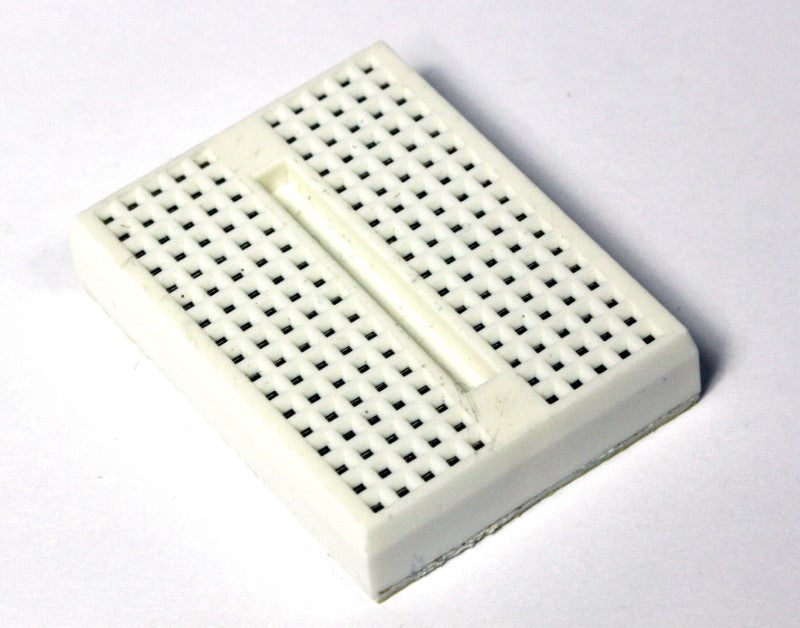

Mini Prototyping Breadboard Self Adhesive - White

Mini Prototyping Breadboard Self Adhesive - White

Couldn't load pickup availability

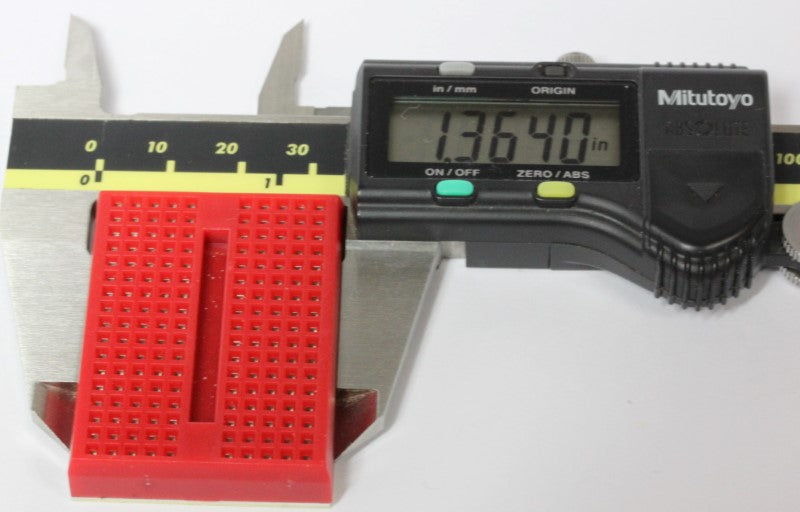

Mini Breadboard 17x10 with a self adhesive on the back. White color. Measures 1.365 inches x 1.8 inches with a thickness of .375 inches. These modular breadboards are great for prototyping and tiny projects. They are half the size of a half-sized breadboard. Hence the term "mini breadboard". The mini breadboard comes with 170 tie points (17x10). Each breadboard measures 1.365 inches (34.67mm) x 1.8 inches (45.72mm) x .375 inches (9.52mm). The self adhesive on the back is easily removable for quick and seamless attachment to your device.

Share

Questions & Answers

Have a Question?

-

What is the dot resolution (size) of the BlackTooth laser?

The dot resolution of the blackTooth is a combination of two specifications of the machine: - The steps/inch (or steps/mm) which is the resolution but not the dot size - The size of the actual dot, which is not specifically related to the resolution. The steps per or resolution can actually be a range, since the driver microstepping can be modified. A simple formula can be used to determine the resolution: step per inch = (motor steps * microstepping) / (travel at one turn of the motor in inches) if microstepping is set at 16 (1/16 on the driver) and you are using a pulley that has a pitch of .08 inches and 20 teeth on the drive sprocket = (200 steps * 16 microsteps) / (20 teeth * .08 inches) = 3200 steps / 1.6 inches = 2000 steps per inch To increase the resolution, just increase the microsteps on the driver. The actual dot size will depend on the lens you are using, the material being lased, the time period that the laser energy is applied to the material, and the focal height of the lens to the work surface material. The energy from the laser will converge to a point and create a dot on the surface (which is different than the kerf of the laser cut into the material). The dot will appear in different sizes depending on the material because, say wood, will burn causing a dot that burns the fibers of the wood and spreads a bit. The dot lased on the surface of a plastic, say Plexiglas, the dot will be smaller because the energy is absorbed only at that point, but since Plexiglas is a thermoplastic, a bit of the energy will melt the dot edges depending on the time frame (period) that the energy is applied to the surface. The focus of the laser energy from the lens looks like a cone converging to a point, then diverges outward after that point. Depending on the distance from the lens to the surface of the material, the dot will be bigger or smaller. You want to find focal point (where the energy is focused into a point). You can use the technique where you lay a material on a slope and lase that material along the slope to find the sweet spot (dot) and that will be your smallest dot, or kerf location. Remember that the kerf will widen or narrow within the material thickness depending on the focal length lens specification (the cone will be shorter or longer depending on the lens focal length).

-

The cooling fan on my power supply has quit. Can I purchase just the replacement fan?

Yes, we can sell that size of fan replacement. Can you provide the type of power supply that you purchased? Additional Information: APS02HT86-320-36

-

My X axis motor runs normally at a jog rate or 2-10% , but makes a loud noise at any higher jog rate

A couple of things you can try to reduce the noise of a motor. First, change the amp setting on the driver to a lower value. This will make the initial thump lighter, and cause the motor to run quieter, but the torque may not be as high as desired. Second, increase the micro stepping to a higher value, like 1/16 (3200) instead of 1/8 (1600), for instance.

-

I am looking at 2 of your motor drivers. 1 is the 1/64 step and the other is 1/256. What is the difference between the two?

Stepper motors are designed to move in specific increments; these increments are called "steps". For example, a common standard is for 200 steps per full revolution. Microstepping is a method to send signals to the motor to move only a fraction of a full step at a time. For example, if a motor has 200 steps per revolution and is microstepped 1/16, then effectively there are 3200 small step movements (microsteps) per revolution instead of 200 larger ones. This makes the motion of the motor much smoother and more precisely controllable, at the cost of decreased holding torque. Here are is a good references for stepper motor theory: http://users.ece.utexas.edu/~valvano/Datasheets/StepperMicrostep.pdf And Wikipedia has a good overview as well: https://en.wikipedia.org/wiki/Stepper_motor