BuildYourCNC

1/2" Lead Screw (2 turns per inch)

1/2" Lead Screw (2 turns per inch)

Couldn't load pickup availability

1/2" ACME Precision Lead Screw - 5 Start, 10 TPI (2 Turns Per Inch)

Product Overview

This high-precision 1/2" ACME lead screw is engineered to deliver exceptional performance as the primary mechanical component for CNC machine axis movement. Featuring a 5-start, 10 TPI configuration that translates to 2 turns per inch, this lead screw provides the precise, reliable motion control essential for professional CNC applications.

Key Specifications

- Diameter: 1/2" outside diameter

- Thread Type: ACME precision (square threads)

- Starts: 5 start configuration

- Threads Per Inch: 10 TPI

- Lead: 2 turns per inch

- Maximum Continuous Length: 72"

- Material: Precision-machined steel

Enhanced Performance with Anti-Backlash Nut

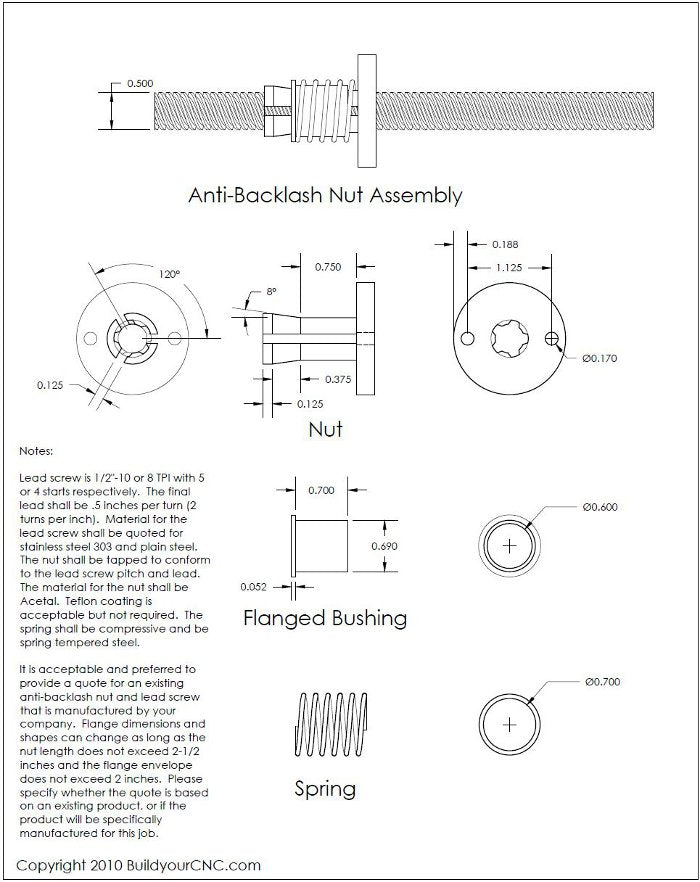

When paired with our matching anti-backlash nut (same specifications), this lead screw combination delivers superior precision by virtually eliminating backlash in your CNC system. The anti-backlash nut, also known as a wear compensating nut, automatically adjusts for wear over time, ensuring consistent accuracy throughout the machine's operational life.

Custom Cut-to-Order

Pricing: Per inch (quantity = total inches needed) Processing Time: Additional 1-2 business days for cutting

Ordering Instructions

To order your desired length, simply set the quantity equal to the total inches needed. For example, for a 24-inch lead screw, change the quantity to "24" and add to cart.

Woodsmith 2.0 CNC Machine Plans - Special Package Available For builders following the Woodsmith 2.0 CNC machine plans, we offer a special pricing option that includes all three required lengths: 59-1⁄4", 37-3⁄4", and 17". This package ensures you have all the lead screws needed for your complete build at a discounted rate.

Need Help with Specifications? Use our website chat feature to speak directly with the owner of BuildYourCNC for personalized assistance with determining the ideal cut length for your specific application.

Important Installation Notes

Due to manufacturing tolerances, standard 1/2" ID bearings may require slight adjustment to fit properly on the 1/2" lead screw. If needed, you can:

- Heat Expansion Method: Gently heat the bearing to expand the inner diameter for easier installation

- Lathe Reduction: Use a lathe to slightly reduce the lead screw diameter

- Manual Reduction: Carefully reduce the lead screw diameter using sandpaper or a file

Note: Our lead screws and anti-backlash nuts are perfectly mated for optimal performance.

Why Choose ACME Precision?

CNC machines demand precise, repeatable movement. Backlash in linear motion systems can compromise accuracy and surface finish quality. This ACME precision lead screw and anti-backlash nut combination significantly reduces backlash, ensuring your CNC machine operates with professional-grade precision and reliability.

Perfect for: CNC mills, routers, lathes, 3D printers, and other precision machinery requiring accurate linear motion control.

Share

Instructions

Questions & Answers

Have a Question?

-

do you guys sell full set of lead screws, machined with bearings and mounts?

We sell all of those parts and if you need the lead screw machined to a specific spec, we can do this. To provide the specs, please send an email to us from the contact us page, link located in the footer. If there is a specific part you need, please let us know and we can let you know if we have it, or if we can start carrying it.

-

ReplicatorG is giving a reading of 1024 deg C on my extruder. Replaced thermistor an have same reading. What is wrong?

The reason you are getting a reading of 1024C in replicator-G and you are using a thermistor and you are using our extruder controller, you will have to use a type-K thermocouple rather than a thermistor. The reading is 1024 because the chip used for sensing temp. is designed for thermocouples and the microcontroller's ADC(analog digital converter) is not getting the correct voltage from the chip(thermocouple).

-

GREENLEAN CABLE CARRIER

The greenlean requires a total of 12 feet of cable carrier. On the Y-axis gantry requires 42 inches and the Z-axis(top of the machine) needs 102 inches. The brackets are sold separately.

-

If using a grease how does one protect leadscrews and rails from corian dust etc.

If you have abrasive particles in the air from milling, you will want to periodically clean the mechanical parts like the lead screw and anti-backlash nuts. After cleaning the parts, all of the high friction parts that will be in constant contact, lubricating the parts with oils, grease or other lubricants. If the part is of steel material, that material will definitely need to be oiled, greased or lubricated so minimal oxidation will affect the exterior of the steel parts. The anti-backlash nut is made of Delrin, so petroleum chemicals like oils, grease or lubricants are ok to use. Abrasive particles may affect the anti-backlash nut over time; however, the spring and bushing of the anti-backlash nut will provide extensive use regardless of the wear.

-

If I buy the 1/2" 5 start lead screw and the 3/8" 5 start lead screws will it all work together

If the turns per inch on a lead screw is different, then the nut on the lead screw will move at a different velocity. Additional Information: Let me explain in more detail. Let's say you have two lead screws: - 1/2" 5 starts at 10 TPI = 2 turns per inch. (5 starts / 10 TPI = 1/2 inches per turn or 10 TPI / 5 Starts = 2 turns per inch.) - 3/8" 2 starts at 10 TPI = 5 turns per inch. (2 starts / 10 TPI = 1/5 inches per turn or 10 TPI / 2 starts = 5 turns per inch.) So, if two stepper motors (one connected to the 1/2" lead screw and the other connected to the 3/8" lead screw) turned 10 revolutions in 2 seconds, the 1/2" lead nut would travel 5 inches and the 3/8" lead nut would travel 2 inches at the 2 second mark.

-

I just made the book build Cnc machine with the feed rate of 11.19 inch/min as suggested in book. Can I increase it to 20 inch/min? I have 2hp of router attached

The book (scratch build) will be able to cut at very high rates of speed, but the speed is partly determined by the mechanical setup. Cutting wood is generally recommended between 60-200 ipm depending on the end mill and spindle being used. The larger the end mill (with increased chip load capacity) the faster the feedrate. If you are using a standard allthread, you will not be able to have these high feedrates. You will need to purcahse high lead leadscrews: https://www.buildyourcnc.com/item/mechanical-leadscrews-leadnuts-!5-5-starts-10-tpi The stepping motors need to turn 13 times to travel one inch using standard allthread (1/2-13 TPI - threads per inch). The higher lead leadscrews shown in the link provided will move one inch with only two turns allowing the machine to move many times faster. These speeds are especially important if you are cutting materials that have low melting points like aluminum and thermoplastics like acrylic, Plexiglas, etc. These materials require high feedrates and smaller depth per passes. Additional Information: 20

-

I couldn't find any information about how to mount the "z-axis lead screw in the book" (Build Your Own CNC)

The details will differ depending on the type of lead screw you use. For allthread lead screws, you will need the 1/2" square nut, 1/2" allthread lead screw, two 1/4" screws and nuts to hold the square nut in place, two 1/2" ID bearings, two standard 1/2" nuts, and one coupling hub. Attach the square nut to the nut support using the two 1/4" screw and nuts. The bearings will need to be inserted into the seats of the lower and upper part of the z-axis. Insert the lead screw through the top bearing. Use one of the standard 1/2" nuts and start threading it on the allthread screw just below the bearing. Lower the lead screw to the square nut and start to screw the lead screw into the square nut. Continue until the screw is near the lower bearing. Add another standard 1/2" nut to the screw and keep turning the screw until the screw just passes the lower bearing. Add the coupling hub to the top of the screw just above the upper bearing. Turn the lower and upper standard 1/2" nuts until they are snug against the bearing. If the standard 1/2" nuts become loosened, consider adding another nut to each end against the existing nut to keep them in place. For 1/2" acme 5 start lead screws, you will need to use an antibacklash nut in place of the square nut. This nut attaches with a flange using two #8 screws and nuts. The standard 1/2" nuts are replaced by clamping collars.

-

I am having a significant amount of trouble getting the 1/2" ID bearing to fit over the 1/2" 5 start lead screw. I can only get it about half an inch onto the rod. Any tips to get it to slide further?

There should be no problem with getting the 1/2" ID bearing on the lead screw, unless there is a bent in the lead screw or it has a piece of debris that is causing a issue. Unless one of these items were purchased from a 3rd party, then there might be tolerance issues from the original manufacture which might cause this issue. If possible please send photos to customerservice@buildyourcnc.com

-

How do I order specific lengths of lead screws in one order?

Just specify the full length in the quantity field in the shopping cart and give us a call to inform us of the cut lengths (you can also email customer service - link in the contact us page - link at the footer). We are working on a way to do this at the product page, but won't be finished for a few more days. Additional Information: 20

-

Has anyone built the machine from the book plans and made substitutions for the store-bought threaded rod? I wanted to spend a bit more money to ensure smoother/faster/more accurate travel with the lead screws, but i am not sure what to use. Mcmaster Carr has quite a few Acme lead screw options, however the price varies drastically. Any input is appreciated.

You can use any type of threaded rod, i.e. ACME profile, hi-lead, ball screw, etc. The only change you will need to make is the way the lead nut fastens to the nut mount on the machine. Lead nuts for these non-allthread screws typically have flanges with mounting holes, so the mounting of this type of nut is far better than the standard nut used in the book build. These better screw options will also allow your machine to move faster and with less backlash. https://buildyourcnc.com/item/mechanical-leadscrews-antibacklash-nut-!5-5-starts-10-tpi https://buildyourcnc.com/item/mechanical-leadscrews-lead-screw-!5-5-starts-10-tpi

-

I want my cnc to move quicker. I want to update my lead screws. will this make my cnc move quicker on all 3 axis. If it would which lead screw is better 2 turns per inch or 5 turns per inch.

Changing your lead screws from a tight to a lose lead will definitely make your machine move faster as long as your stepper motors can handle the new torque that the lead screws will impose. Here is an example of a speed change from one lead screw to another: - Existing constants in the example: Stepper Motor steps 200, microstepping 1/8 making the total steps 200 * 8 = 1600. - Old lead screw: 1/2" allthread = 13 threads per inch (UNC) - New Lead Screw: 1/2" 5 starts, 10 TPI = 10 / 5 = 2 turns per inch Old lead screw would achieve a steps per inch of: 1600 / (1 inch / 13 turns) = 20,800 steps per inch (You can also express the calculation as 1600 * 13 = 20,800 steps/inch) New lead screw would achieve a steps per inch of: 1600 / (1 inch / 2 turns) = 3200 steps per inch You can see that the new lead screw requires far fewer steps to get to the same length of travel. If you maintained the same velocity for both examples, the new lead screw would travel the same distance 13/2 = 6.5 times faster. So, if your velocity was say 10 ipm, your new velocity would be 65 ipm. That would translate to far fewer burned edges and longer end mill life! Just remember, confirm that your motors will be able to handle the new lead screw. You will need to reduce the steps/inch causing the motor torque to increase quite a bit, so you should be fine.

-

For the 1/2'' 5 start ACME leadscrew, what is the length purchased for the $2.00 order? and if you make 2 orders, are you getting two separate rods or 1 rod at twice the length. Thanks.

We sell our ACME screws in total length (overall length you require), but if individual lengths are needed you can contact us via phone (281-815-7701) or email (customerservice@buildyourcnc.com). A $2.00 order will be a total of 1 inch, but if ordered separately then you will receive 2 of the same length.

-

Hi m8 I have spoken yo u guys b4 about 1/2 inch lead screws and nuts to Australia before my names Troy evans I work for arkedout metalwaorks... could u get a full quote for me of 2 x 1/2 inch 5 start lead screws 1700mm long and acetyl anti back lash nuts to suit ....to 1098 old port road Hendon 5014 south australia.....I need to get these to extend my existing table

Sure, please email me at customerservice@gmail.com or phooddaniel@berkeley.edu.