BuildYourCNC

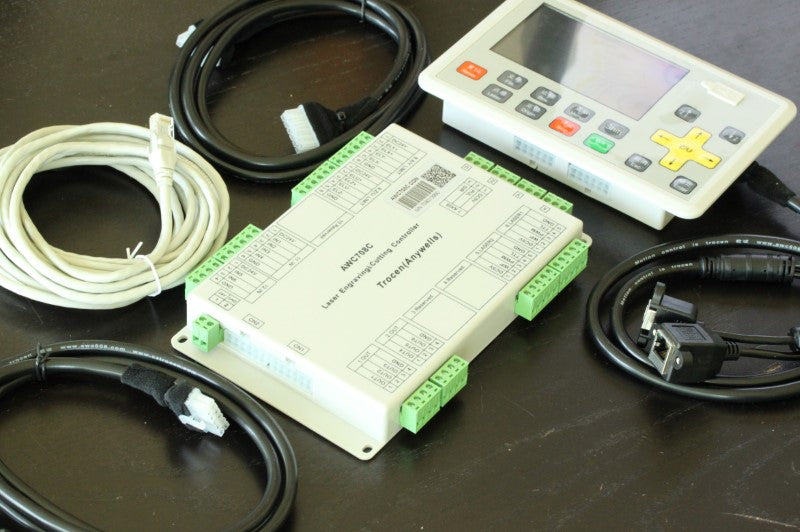

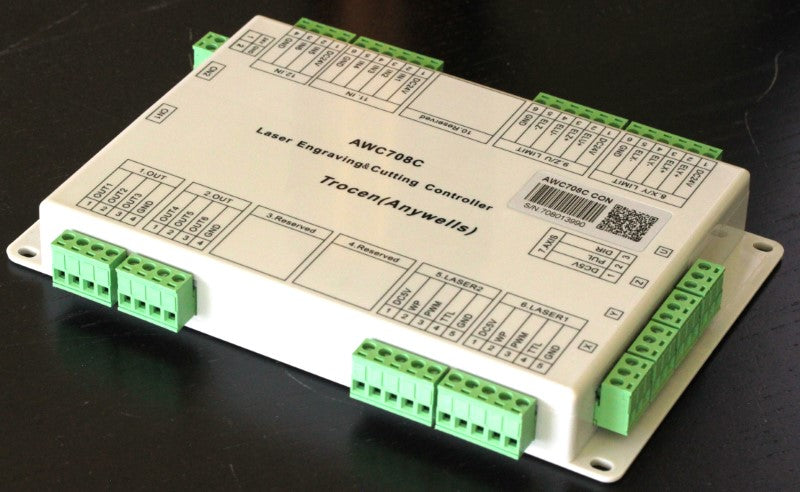

Laser Control System

Laser Control System

Couldn't load pickup availability

- CorelDraw and AutoCAD plugins

- PWM or Analog output

- Multiple motor configuration

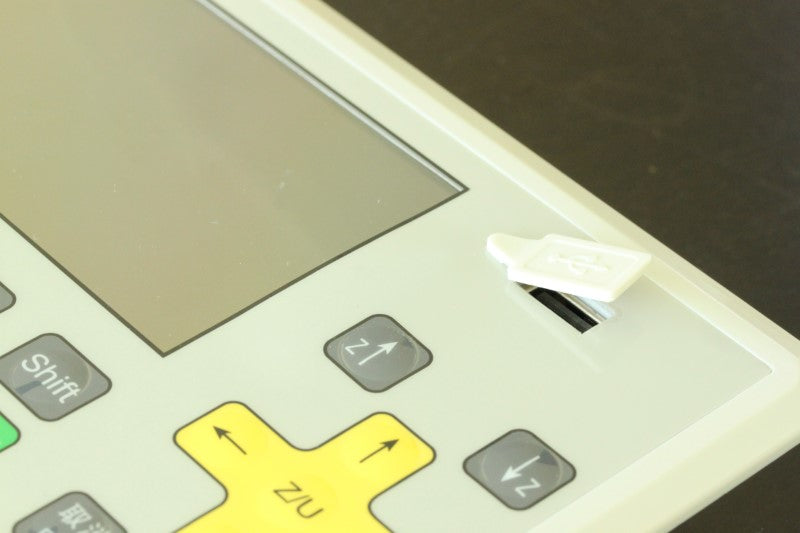

- LCD panel - onboard speed and power control

- Memory recovery after power surge

- Vector and Raster support

- Interface port: USB or Networking

- Per layer PPI control

- Multiple layers for speed and power control

- Multiple pass engraving or cutting per layer

- Power: DC 12~36V, 1.5A

- OS Compatibility: Windows 8/7/XP/2000 32 bit - 64 bit w/ driver

- Format Drive to FAT32

- Load work file on drive and change file name extension to .ud5

- Insert USB drive into USB slot on the Control Unit's motherboard

- Go into Menu on the Control Unit Interface, select "Udisk" and then "Work files".

- Select the work file and it will load onto the screen.

Share

Questions & Answers

Have a Question?

-

Do you have a laser kit that can be fitted onto another brand CNC router?

We don't have a laser kit to retrofit another CNC router other than ours, but we can create one. Some things that may help: - You are located close to use so we can work closely with you to implement to retrofit, - or you can provide very detailed drawings or measurements so we can use them to create the necessary parts for the kit. Other things that you need to understand: - A laser has a number of parts that will bulk up the head of the CNC router causing a bit more inertia which may require lowering the acceleration for smooth ramping up and down of the velocity - The bulk of the parts required for the laser may restrict the travel of the x and/or y axes. - The nozzle of the laser will be offset from the end mill of the spindle. Can you tell me the brand of the CNC router that you would like to stick a laser on? (you can answer by submitting additional information.

-

CNC Plans Kit with a laser cutting tool added to it

it is possible to add a cnc laser cutter to your machine. However, you will need to construct a holder that would mount on the X-Axis. Additional material you would need to buy would be the laser tube, mirrors, mirror mounts, controller, and chiller. You can add more components but it will depend on what you want to achieve.

-

can you supply a new board and a better software program for a CO2 laser cutter and engraver

If you need a new laser controller for CO2, we can definitely supply one. This is the laser controller that we sell: https://www.buildyourcnc.com/item/Laser-Component-Laser-Control-System The laser controller works with a program called LaserCAD and is compatible with most typical file types. The laser controller will work with any laser tube and laser tube power supply that requires 5V digital signals and PWM.

-

I wish to laser engrave wood drum shells. (musical instrument) A X axis with a 3 roller system, 2 passive inside the cylindrical shell, one driven to move the shell around it's circumference would suit my needs. I have 20 design engineering in my past, I could design up what I need in Autocad but have no idea how to automate the system and make it work. college was 20 years ago lol! Help!

If you need to create a laser engraving system that engraves on a large rotating drum. You will need the motors, drivers, laser control system, laser tube, power supply for the laser and motion drives, and the mechanical and structural components to turn the drum (X axis) and move the y axis.

-

i have purchased the laser control does it have an software and can i run this from my computer instead of using a thumb drive

Yes, the laser controller comes with software (LaserCAD), and you can indeed use your computer to communicate with the controller.

-

I am looking at using a laser on my 6X6 3 axis table what do i need?

To add CO2 laser functionality to your existing CNC machine, you will need everything listed on this page: https://www.buildyourcnc.com/LaserComponents.aspx The number of mirrors and mirror mounts will depend where and at what orientation the laser tube will be mounted in the machine. There is already a mirror mount in the head/nozzle unit, so keep that in mind.

-

How to wire the Laser Power Supply with an arduino & GRBL ? (I'm not using a blacktooth laser cutter)

There is a th or tl on the laser power supply that serves as the trigger on a high or low signal. There is also a potentiometer "in" terminal that will accept a variable signal from 0v to 5v to control intensity. You can use either of these features to fire the laser tube. If you have gotten grbl to work, then, no doubtedly, you have the expertise to know the output features of grbl. If grbl allows a pwm output, you can tie this to the potentiometer terminal on the power supply. Otherwise, you will need to use a digital output to control the power supply using th or tl. Additional Information: Additional Information: Additional Information: Additional Information:

-

How to I wire a (burning) laser unit to a breakout board?

Are you asking how to wire the laser tube power supply to the breakout board? Additional Information: I have power coming from the battery pack through the circuitboard but for some reason I�m not getting that power to the front part of the laser once it�s connected am I missing a ground wire

-

DOES ZY PLATE COME WITH LASER HEAD COMBO.

No the ZY plate is part of the machine kit not the head combo kit.

-

Can the Planet CNC USB controller be used with a laser engraver/cutter? Can the build your own CNC based on the Planet CNC USB controller accept a Laser head instead of a router?

The PlanetCNC USB software, like most machine control software, can be used to control a laser engraver/cutter. The typical modification is to use the Z axis down signal to fire the laser, analogous to an endmill cutting into the workpiece from an initial position above it. For the second question, it is important to note that BYCNC machines are not based on PlanetCNC software, or any other particular machine control system. The machines themselves will accept standard signals from a wide variety of machine control systems, not just PlanetCNC or Mach3. This allows maximum flexibility for the customer to choose their own preferred software for this part of the toolchain. That said, our machines will accept a laser head either in lieu of or in addition to a spindle. Here is an example of a combination spindle/laser mount for our greenBull machine: https://buildyourcnc.com/item/cnc-machine-laser-spindle-combo-head. We have all the parts you would need to add laser functionality to your machine here: https://buildyourcnc.com/LaserComponents.aspx, if you feel comfortable assembling your own package. Also, feel free to contact our sales department for a quote if you need a custom assembly.

-

Can other types of laser tubes work with the controller you are selling, for example, the 80W Reci tube?

Yes, other CO2 laser tubes will work fine with our laser controller (including the Reci tube). Our laser controller is a digital based controller that controls the laser tube power supply, the motor drivers and other peripherals by outputting digital signals to these devices. Laser controller URL: https://www.buildyourcnc.com/item/Laser-Component-Laser-Control-System

-

Can the RuiDa RDC6442G laser controller be used for plasma

That's an insightful question. My initial impression suggests that it is indeed possible. The trigger for the plasma torch can be activated by a high or low signal, which can be conveniently managed using a relay. However, one potential challenge might be the absence of torch height control in laser controllers such as the Ruida. Nonetheless, if you can address this height adjustment through mechanical means, which many machines are capable of, utilizing the Ruida controller for plasma applications should not pose any significant issues.

-

Can this be used to control a spindle as well as a laser?

It is possible to wire this controller so a spindle can be turned on and off, but spindle speed would not be possible and would need to be controlled from the control panel. It is not recommended to use a laser controller to control a spindle as a laser controller is specifically made for lasers to control speed and intensity. A traditional CNC controller is best to be mated with a system that uses a spindle as there are more sophisticated machining operations that take into consideration the features of a tool (end mill, drill, surfacing tool, etc.). Additional Information: I would recommend creating a system, similar to the greenBull, where there are two gantries on a single table where one gantry houses a spindle and the other gantry houses a laser. Each gantry can use a disparate controller, but be mapped/calibrated/aligned to the same surface.