Instructions

1

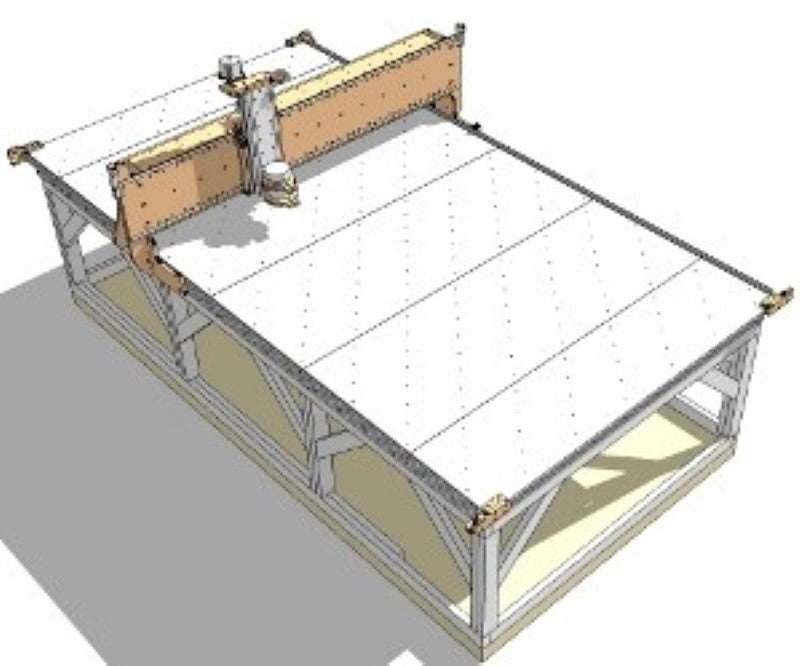

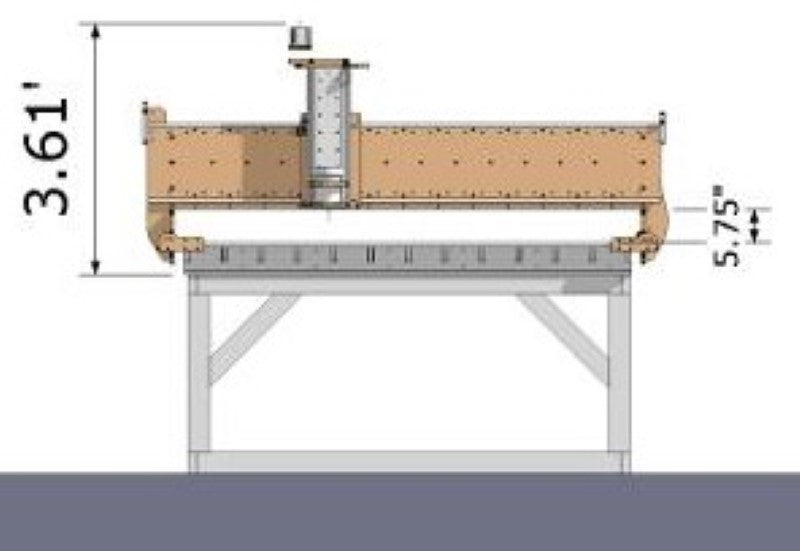

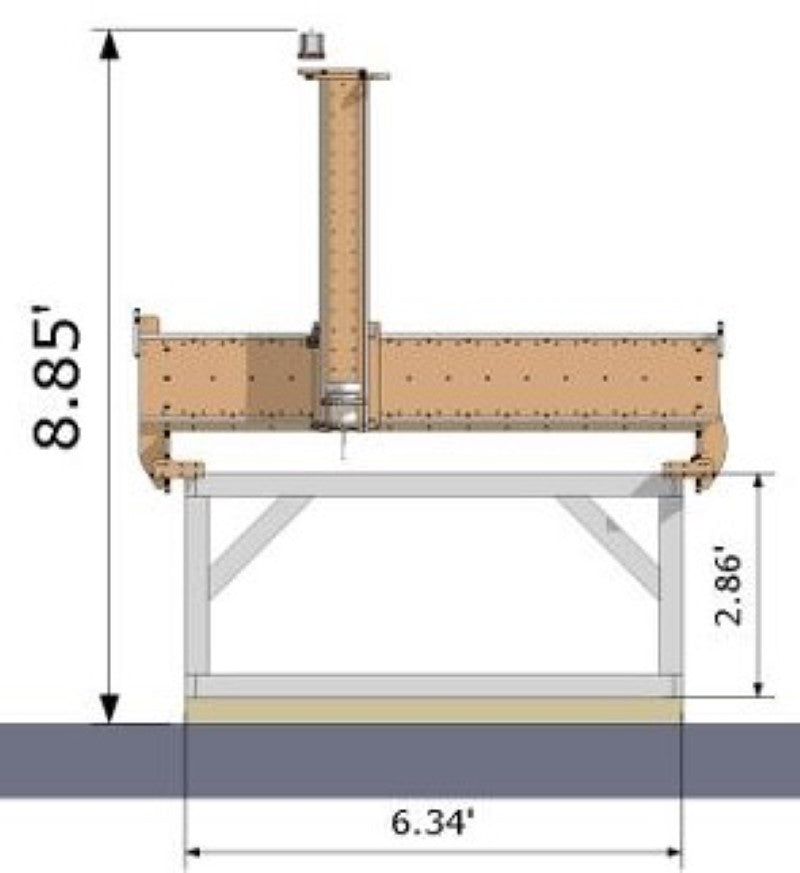

This is a demonstration of how one of our customers uses the greenBull CNC router.

2

An example of the greenBull CNC router cutting extruded aluminum.

3

The greenBull CNC router cutting aluminum. An explanation of the tool (end mill) used, feedrates and depths per pass, and the chips that are ejected from the cutting action.

4

This is the greenBull CNC router cutting full depth into 3/4" plywood and testing the dust extraction using flexible plastic material. We don't use this technique as we have found that brush is adequate and brush is what is delivered with the purchased machines.

5

Surfacing the spoilboard with the greenBull CNC router. Surfacing should be done frequently to provide the best finish at the underside of the workpiece.